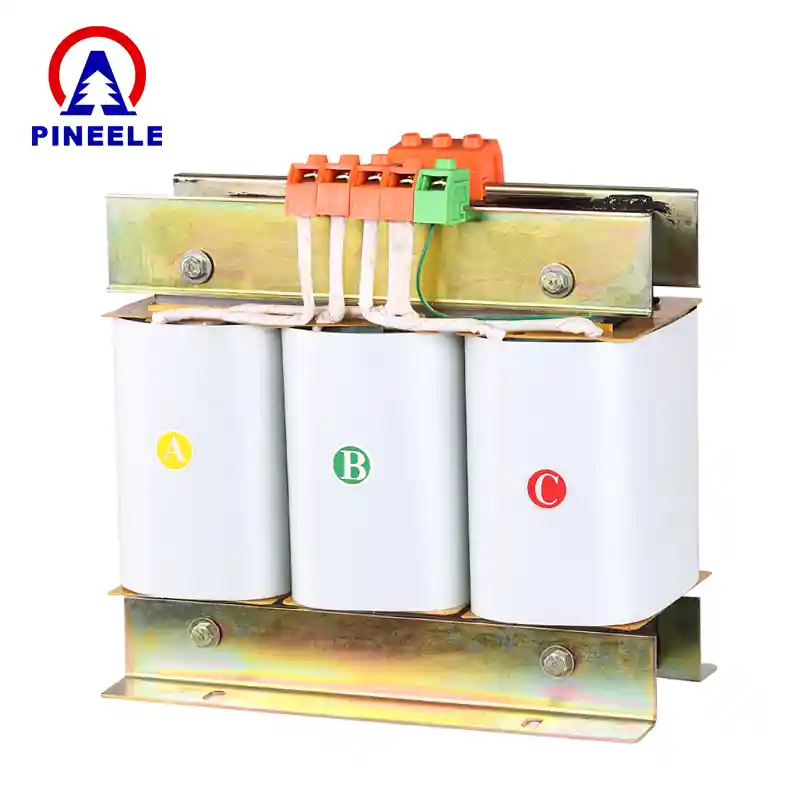

The SBK Three-Phase Dry Type Transformer is an advanced, reliable, and efficient power distribution solution designed to meet diverse industrial and commercial applications. Featuring superior engineering, robust construction, and versatile functionality, the SBK series delivers exceptional performance, ensuring stable and safe power distribution in various environments.

Structural Overview

The SBK Three-Phase Dry Type Transformer is available in two primary structural configurations: open-type and protective-type, catering to different operational and environmental requirements. These transformers offer low loss, minimal operational noise, excellent fire resistance, and environmentally friendly operation, free from pollution and hazardous substances.

Core and Coil Design

At the heart of the SBK transformer is a premium-quality iron core constructed from cold-rolled silicon steel sheets. The design and assembly ensure minimized energy loss and efficient heat dissipation, enhancing operational reliability and longevity. The transformer coils, meticulously wound using advanced winding techniques, significantly reduce electromagnetic interference and distortion, thereby maintaining output waveform integrity identical to the input waveform.

Protective Enclosure

The protective-type SBK transformer is enclosed within a robust steel housing, providing superior protection against dust, moisture, and mechanical impacts. This enclosure is thoughtfully designed with inlet and outlet cable entry points, enabling straightforward and safe electrical connections. Depending on user requirements, additional components like voltmeters, ammeters, temperature controllers, and casters can be incorporated, offering enhanced mobility and real-time operational monitoring.

Versatile Applications

SBK series transformers are versatile and categorized into control transformers and lighting transformers. Control transformers are typically stationary, optimized for industrial machinery and automation systems. Lighting transformers, however, are primarily portable, suitable for a wide range of applications including construction sites, workshops, manufacturing plants, and commercial buildings, except for those specifically used in machine tools.

Normal Usage Conditions

To achieve optimal performance and maintain reliability, SBK transformers should operate under standard conditions:

- Altitude: Installation altitude should not exceed 2000 meters.

- Temperature: Ambient air temperature should remain within -5℃ to +40℃, with a maximum average daily temperature not exceeding +35℃.

- Humidity: Relative humidity should be below 50% at +40℃, though higher humidity levels (up to 90%) are permissible at lower temperatures (+20℃).

- Environmental Stability: Installation sites must be free from severe vibrations, shock, or explosive hazards, and should not contain corrosive gases or conductive dust.

Customized Voltage Configuration

A key benefit of the SBK transformer is its customizable input and output voltage capabilities, tailored to user-specific needs. This flexibility allows integration into diverse electrical systems, accommodating unique voltage requirements seamlessly.

Technical Parameters

| Parameter | Specification |

|---|---|

| Product Name | Dry Type Transformer |

| Model | SBK series |

| Output Voltage Accuracy | ±1% |

| Phase | Three-phase |

| Capacity | 0.5KVA to 2000KVA |

| Input Voltage | Customizable |

| Output Voltage | Customizable |

| Voltage Change Rate | ≤1.5% |

| Output Waveform Distortion | No distortion (compared to the input waveform) |

| Insulation Class and IP Rating | Class F, Class H, HC; IP00, IP20 (typically Class F) |

| Work Efficiency | ≥98% |

| Frequency | 50Hz/60Hz |

| Connection Method | Y/Δ |

| Overload Capacity | Can operate at 1.2 times rated load for 4 hours |

| Noise Level | ≤35dB |

| Temperature Rise | ≤60℃ |

| Insulation Resistance | ≥150MΩ |

| Design Life | 30 years |

| Working Environment | Temperature: -20℃ to +45℃; Humidity ≤95% RH (non-condensing) |

| Workplace | No corrosive gases or conductive dust |

| Safety Standards | Compliant with VDE0550, IEC439, JB5555, GB226 |

| Cooling Method | Dry air cooling |

Advantages and Features

The SBK Dry Type Transformer stands out due to its array of advantages:

- High Efficiency: With efficiency ratings exceeding 98%, the SBK transformer minimizes power loss, ensuring substantial energy savings and reduced operational costs.

- Enhanced Safety: The dry-type design eliminates oil leakage risks, reduces fire hazards, and enhances environmental safety, making it suitable for sensitive and enclosed environments.

- Maintenance-Friendly: Constructed without liquid cooling mediums, the SBK transformer requires minimal maintenance, reducing downtime and associated costs.

- Durability and Longevity: Utilizing high-quality materials and advanced manufacturing processes, the transformer provides reliable performance over its 30-year expected lifespan.

- Low Operational Noise: Operating noise levels remain below 35 dB, ensuring quiet operation suitable for environments where minimal sound disruption is essential, such as hospitals and residential areas.

Application Fields

The SBK series is extensively utilized across various sectors:

- Industrial Facilities: Essential for powering machinery, production lines, and automation systems.

- Commercial Buildings: Ideal for lighting, HVAC systems, elevators, and electronic equipment power supply.

- Construction Sites: Provides reliable temporary power solutions for tools, equipment, and lighting.

- Healthcare and Laboratories: Ensures stable, isolated power crucial for medical equipment and precision instruments.

The SBK Three-Phase Dry Type Transformer series represents an optimal choice for businesses and industries requiring safe, reliable, and customizable power solutions. Backed by high-quality construction, innovative design, and rigorous adherence to international standards, the SBK transformers ensure stable performance, long-term reliability, and unmatched safety in diverse operating environments. This transformer series is more than just a power distribution device; it is an investment in operational excellence, energy efficiency, and sustainability.