Introduction to GCK Low Voltage Switchgear

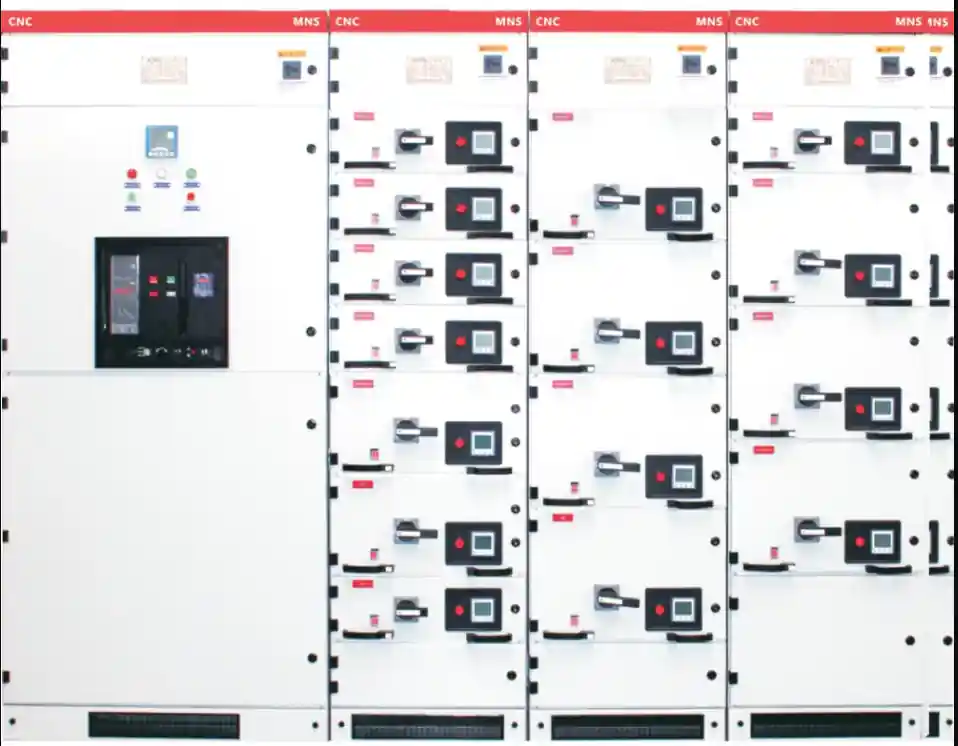

The GCK Low Voltage Switchgear, a withdrawable-type modular panel system, is designed to meet the demanding control, distribution, and reactive power compensation needs in modern Voltage Switchgear environments. This versatile system is widely applied in large-scale power stations, petrochemical enterprises, automation-intensive sectors, and facilities requiring advanced communication capabilities with monitoring computers.

With a protection rating of IP30 or IP40 and conforming to IEC 60439-1, the GCK Voltage Switchgear ensures safety, efficiency, and ease of maintenance across industrial, commercial, and infrastructure applications.

Key Features of the GCK Low Voltage Switchgear

- Withdrawable Functional Units: Support feeder, motor, and utility power units with drawer sizes customizable from ½ to 3-unit height.

- Three-Zone Separation Design: Cabinet is compartmentalized into busbar, functional, and cable areas for safety and maintenance.

- Interlocking Mechanism: Drawer positions feature mechanical interlocks for working, testing, and isolation stages with lockout capability.

- Modular Frame Structure: Standardized components with 25mm E-module grid for flexible configuration.

- High Busbar Capacity: Rated up to 5000A for horizontal busbars with robust short-circuit withstand capabilities.

Technical Specifications of GCK Low Voltage Switchgear

Electrical Specifications

| Item | Value |

|---|---|

| Rated Insulation Voltage | 690V / 1000V |

| Rated Operational Voltage | 400V / 690V |

| Rated Frequency | 50 / 60 Hz |

| Rated Impulse Withstand Voltage | 8kV |

| Rated Voltage of Auxiliary Circuit | AC380V / AC220V / DC110V / DC220V |

| Overvoltage Grade | III |

| Rated Current | ≤5000A |

| Horizontal Busbar Current | ≤5000A |

| Vertical Busbar Current | 1000A |

Mechanical & Structural Features

- Incoming/Outgoing Mode: Cable or busbar type, top or bottom.

- Mounting System: Modular with interchangeable components.

- Compartmentalization: Full/partial isolation for enhanced safety.

- Modular Units: ½ unit to 3-unit drawer modules.

- Earthing: Continuous grounding through galvanized internal structure.

- Operation Types: Local, remote, and automatic operation.

Construction and Materials

1. Cabinet Frame

- Constructed with C-type steel or KB-type assembly structures.

- Electrostatic epoxy powder coating with phosphating pretreatment.

- Removable top cover for easy busbar installation.

- Internal parts are galvanized for anti-corrosion and electrical continuity.

2. Functional Units

| Drawer Height | Series | Application |

|---|---|---|

| ½ Unit | 100mm | Low power feeders |

| 1 Unit | 200mm | Motor starters |

| 2 Unit | 400mm | Medium feeders |

| 3 Unit | 600mm | High capacity loads |

- Maximum of 18 drawers (½ unit) or 9 drawers (1 unit) per MCC.

- Rated current: up to 630A per functional loop.

- Interlock protection between drawer and operation mechanism.

- Position indicators for: working, test, isolation.

3. Busbar System

- Busbars arranged at top or bottom based on configuration.

- Horizontal busbars: 3P4W / 3P5W structure.

- Vertical busbars sealed with polycarbonate plastic.

- PE and N busbars available as per protection requirements.

Cabinet Dimensions & Installation

General Dimensions (mm)

| Type | Width | Depth | Notes |

|---|---|---|---|

| Power Cabinet | 600 / 800 / 1000 / 1200 | 800 / 1000 | Top incoming/outgoing uses 1000mm |

| Feeder Cabinet | 600 / 800 | 600 / 1000 | Recommended 1000mm depth |

| Motor Control Cabinet | 600 / 800 | 800 / 1000 | 600 + 200 configuration optional |

| Compensation Cabinet | 600 / 800 / 1000 | 800 / 1000 | Based on number of loops |

Copper Busbar Specification

| Rated Current (A) | Copper Busbar Size (mm) |

|---|---|

| 630 | 50 × 5 |

| 1250 | 60 × 10 |

| 1600 | 80 × 10 |

| 2000 | 100 × 10 |

| 2500 | 2 × (80 × 10) |

| 3150 | 2 × (100 × 10) |

Functional Highlights of Voltage Switchgear

- Modularization: Equipment and component interfaces designed on a 25mm E-grid for easy plug-and-play replacements.

- Safety First: Functional units are electrically and mechanically isolated during drawer extraction.

- Control Flexibility: Supports local and remote operation with intelligent control units.

- Reliability and Continuity: Rear-mounted auxiliary and earthing plugs ensure continuous operation without arc exposure.

- Expandable Design: Easily add power loops, feeders, or motor units as demand grows.

FAQ: Common Questions about GCK Voltage Switchgear

Q1: What distinguishes GCK Voltage Switchgear from other low-voltage systems?

A: GCK Voltage Switchgear stands out with its modular withdrawable drawers, complete compartmental separation, and support for automation, making it ideal for applications that require flexible and intelligent power management.

Q2: Can GCK Voltage Switchgear support automation and remote monitoring?

A: Yes, the system supports long-distance and automatic operations, making it suitable for integration with SCADA and other intelligent energy management systems.

Q3: How many drawers can a single MCC unit support?

A: A single MCC unit can support up to 18 drawers of ½ unit size or 9 drawers of 1 unit size, allowing high-density configuration and efficient space utilization.

Benefits of Using GCK Voltage Switchgear

- Enhances safety through mechanical interlocks and physical isolation.

- Reduces downtime with drawer-based maintenance and rapid replacement.

- Increases operational intelligence through remote monitoring capabilities.

- Scales easily with modular frame and expandable busbar system.

- Ideal for environments demanding Voltage Switchgear performance with high reliability and automation.

Ordering Information

To customize your GCK Voltage Switchgear system, please provide:

- Main and auxiliary circuit diagrams.

- Cabinet outline and installation dimensions.

- Quantity and specifications of drawer units.

- Incoming/outgoing mode and operation type.

- Any custom modifications or automation requirements.